Vibration monitoring and analysis inside an automotive components plant

Applications

Location: Poland

Site monitored since: September 2017

overall tasks

The Automotive components plant is located in Warsaw - Poland, the production line is equipped with three vibrational conveyors, and four wheel blasting machines. Excessive vibration was observed on the first floor of office building near casting line. The level of human perception of vibration is described by a polish norm PN-B-02171 (similar to BS 6472:2008) , this level was was exceeded several times. People working on the first floor were complaining about excessive vibration. The target of Simdes Partner, a polish consulting group was to identify source of vibration, analyze the building structure analysis and detect presence of resonance phenomena .

EQUIPMENT USED

Caption 1:Floor vibration measurement: BeanDevice® 2.4GHz AX-3D ±2G

Caption 2: Conveyors machines are monitored with our wireless accelerometers (Ref: BeanDevice® 2.4GHz AX-3D)

Data analysis tools:

FFT (Fast Fourier Transform) and one-third-octave bands data filtering scripts are developed with Python (PN-B-02171 standard compliant)

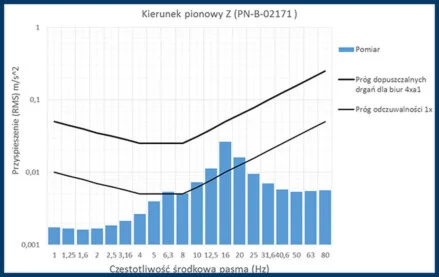

Caption 3: Vibration activity on vertical direction(RMS)

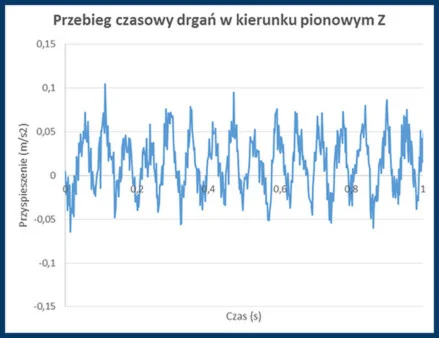

Caption 4: Vibration activity on vertical direction

Caption 5: FFT Analysis according to Polish Standard (PN-B-02171)

Results and Conclusion:

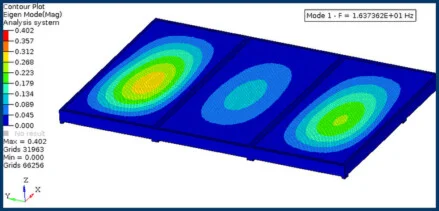

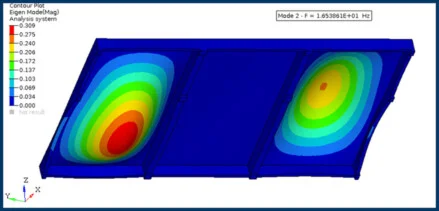

The floor vibration frequency was identical to the vibration frequency of one of the vibration conveyors and coincide with first natural ceiling mode, resonance phenomena has occurred. Customer was advised to change vibration conveyors dumpers and reinforced cellings.

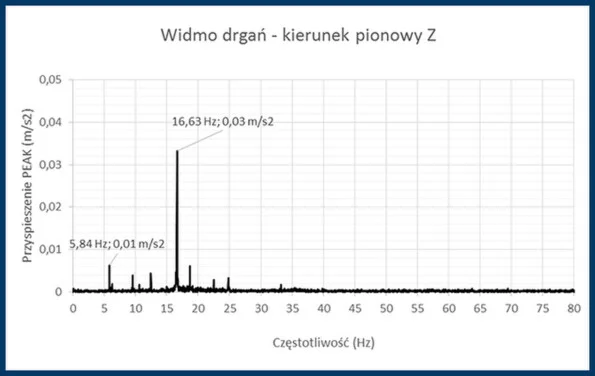

Caption 6: Frequency domain on vertical direction