Test and Measurement

Revolutionizing Test and Measurement with True Flexibility

BeanAir's cutting-edge wireless technology provides unparalleled flexibility for your test benches, offering comprehensive solutions for the rolling stock, naval, and aeronautic manufacturing sectors. By aiming to significantly reduce the costs associated with test bench instrumentation, BeanAir empowers industries to enhance efficiency and innovation.

A Broad Spectrum of Applications

• Automotive: Conduct rigorous tests on raceways, dirt tracks, and in wind tunnels. Our technology is also ideal for comprehensive laboratory test benching.

• Railway: Implement real-time vibration monitoring on train wheels and automate fault detection on critical systems and devices, ensuring the safety and reliability of your rolling stock.

• Aeronautic: Enhance passenger comfort with precise measurements, streamline flight test procedures, and implement robust Health and Usage Monitoring Systems (HUMS).

• Naval: From tracking and surveillance to underwater test benching and engine room monitoring, our wireless sensors provide reliable data in demanding marine environments.

Engineered for the Most Demanding Environments

BeanAir has pioneered a new generation of rugged, miniaturized wireless sensors, specifically engineered to deliver uncompromising performance in harsh industrial conditions. These sensors are built to withstand the rigors of demanding applications, ensuring accurate and reliable data collection where traditional wired sensors fall short.

To provide optimal flexibility, we offer two distinct sensor series tailored to your specific needs:

• 2.4GHz Sensor Series: This series operates on a proprietary 2.4GHz frequency, offering exceptional immunity to interference, even in environments saturated with other 2.4GHz devices. This ensures a stable and reliable data link for your most critical measurements.

• WiLow® Sensor Series: Built on standard Wi-Fi technology, the WiLow® series ensures seamless and effortless integration into your existing IT infrastructure. This simplifies deployment and allows for immediate data streaming to your established systems.

Unlocking High-Fidelity Dynamic Measurements

With a high sampling rate of up to 2KHz available on both sensor series, our wireless technology makes capturing high-speed, dynamic events a reality.

This enables:

• Precise Shock Measurement: Utilize our intelligent Smart Shock Detection (SSD) technology to accurately capture and analyze transient shock events with exceptional detail.

• Accurate Tilt Monitoring: Reliably monitor the angle and inclination of critical structures and components in real-time.

• In-Depth Vibration Analysis: Gain detailed insights into the vibrational behavior of your equipment, enabling predictive maintenance and performance optimization.

BeanAir's sensor technology is synonymous with exceptional reliability, versatility, and maintainability, all delivered in a solution that is remarkably easy to deploy.

|  |

BeanDevice® Wilow AX-3D Wireless IoT Vibration Sensor ►►Go to Page | BeanDevice® 2.4GHz AX-3D-SR Wireless IoT Vibration Sensor ►►Go to Page |

|  |

BeanDevice® Wilow HI-INC Wireless IoT Inclinometer Sensor ►►Go to Page | BeanDevice® 2.4GHz HI-INC-SR Wireless IoT Inclinometer Sensor ►►Go to Page |

|  |

BeanDevice® Wilow AX-3DS Wireless IoT Shock Sensor ►►Go to Page | BeanDevice® 2.4GHz AX-3DS Wireless IoT Shock Sensor ►►Go to Page |

A Sensing Technology Dedicated to Embedded Measurement

Slash Cabling Costs and Complexity

The

expense of cabling in embedded devices and equipment is a growing concern. The

costs of integration, maintenance, and the sheer weight of extensive wiring

introduce significant constraints that often outweigh the price of the cables

themselves. BeanAir offers a transformative solution: slash these costs by

embracing a wireless instrumentation approach. Wireless sensors eliminate the

need for cumbersome and expensive cabling, leading to direct cost savings in

materials and installation time.

Optimized Radio Transmission for Harsh Industrial

Environments

While

many wireless measurement systems struggle in demanding industrial settings,

BeanAir has engineered an innovative solution. Our system is built on the

principle of antenna diversity, a technique that optimizes the quality and

reliability of the radio link in environments plagued by random and diverse

disturbances. This ensures a stable and robust data connection, even in the

most challenging conditions.

Rugged and Miniaturized Wireless Sensors for Unprecedented

Access

Reach previously inaccessible areas

with our rugged and miniaturized wireless IoT sensors. With an IP66/IP67 rating

and resistance to shocks of up to 200G, these sensors are designed to perform

flawlessly in extreme environments. Their compact size allows for deployment in

tight spaces, opening up new possibilities for data acquisition.

BeanScape®: Supervision Software Designed for Your Needs

Seamless Integration and Real-Time Monitoring

The

BeanScape® software provides a powerful, real-time supervision and monitoring

system for your entire network of BeanAir® Wireless IoT Sensors. This intuitive

platform allows you to visualize and manage your data streams effortlessly.

Intelligent Analysis and Proactive Alarms

BeanScape®

is more than just a monitoring tool; it's an expert system. It is equipped with

features that allow for the interpretation of measurements and network alarms,

providing you with actionable insights. The software can be configured with up

to four customizable alarm thresholds, enabling proactive responses to critical

events. Advanced vibration analysis tools, including FFT and Peak Particle

Velocity (PPV) analysis, are also available, with the capability to generate

automatic reports that meet industry standards like DIN4150-3.

Effortless Integration with Your Existing Infrastructure

BeanAir sensors are engineered to fit perfectly within your existing operational technology and IT infrastructure, ensuring a smooth and rapid deployment.

• Industrial System Compatibility (2.4GHz Series): We use Modbus TCP/IP—a trusted and universal protocol in the industrial world. This allows you to reliably feed sensor data from our BeanGateway® directly into your existing PLCs, SCADA systems, and industrial networks with minimal configuration.

• IoT & Cloud Ready (WiLow® Series): Our WiLow® sensors speak the language of modern IoT. By using the lightweight and open MQTT protocol, they can publish data directly to any major IoT cloud platform or data management system, offering maximum flexibility for your smart factory or structural health monitoring projects.

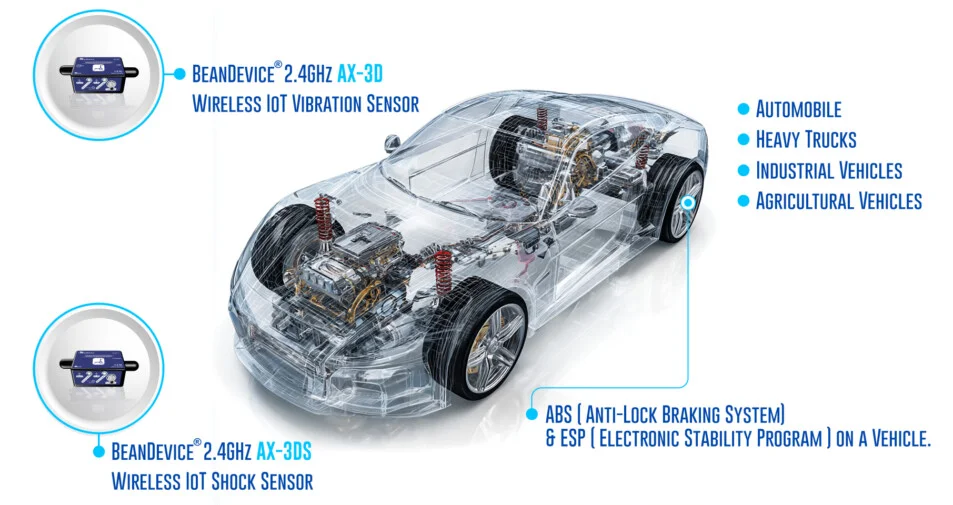

Case Study: Revolutionizing Vehicle Test Benches with Wireless Technology

The Challenge: Simulating a Lifetime of Extreme Conditions

Vehicle test benches are crucial for simulating the extreme conditions a vehicle will endure over its lifespan. From blistering heat and freezing cold to high winds, every component is subjected to rigorous climate exposure tests in specialized chambers. To replicate real-world driving, vehicles undergo demanding test cycles on rollerbeds, testing the clutch, gearshift, and acceleration under various simulated road conditions. The ultimate goal of this exhaustive testing is to ensure every aspect of the vehicle not only meets stringent technical specifications but, more importantly, satisfies customer expectations for performance and reliability.

A multitude of sensors are essential for gathering the critical data needed during these tests. However, traditional wired sensors, while widely used, present significant challenges. They can be intrusive, and their complex wiring harnesses are difficult to deploy across all necessary vehicle parts, potentially interfering with the accuracy of the test results.

The Solution: A "Plug & Drive" Approach with

Wireless Innovation

In a

groundbreaking collaboration, BeanAir® has partnered with an engineering firm

specializing in vehicle test benches for automobiles, heavy trucks, and

industrial and agricultural vehicles. This partnership has produced an

innovative solution that is set to redefine the future of vehicle testing. The

"Plug & Drive" laboratory vehicle concept leverages the power of

wireless technology to push the boundaries of testbed instrumentation.

A key

application of this technology is in vehicle brake system testing. By coupling

our wireless data logger, the BeanDevice® AN-420, with a pressure sensor,

clients can effectively validate critical safety systems like the Anti-lock

Braking System (ABS) and Electronic Stability Program (ESP).

Real-Time Monitoring for In-Depth Analysis

All

measurements are meticulously recorded and stored on the BeanScape® platform.

Each data point is time-stamped in real-time with a 1Hz bandwidth. This allows

for a comprehensive and efficient analysis of a vehicle's behavior, with the

ability to geolocate the vehicle precisely when an alarm is triggered.

The Results: Tangible Benefits in Cost, Time, and Weight

The

adoption of wireless instrumentation delivers significant and measurable

improvements over traditional wired solutions.

Drastically Reduced

Instrumentation Costs and Time

The

"Plug & Drive" laboratory vehicle serves as a compelling example

of the efficiencies gained.

METRIC | Wireless Instrumentation | Wired Instrumentation |

Time & Personnel | 1 Technician for 4 hours | 2 Technicians for 3 days |

Labor Cost | 300 euros (for 1/2 day) | 3600 euros |

Wiring Cost | 0 euros | 400 euros |

Total cost | 300 euros | 4000 euros |

Significant Weight Reduction for Increased Payload

The reduction in cabling and

associated hardware leads to a substantial decrease in the overall weight of

the instrumentation.

Component | Wireless Instrumentation | Wired Instrumentation |

Individual weight | Piezo accelerometer 1 + 4m Teflon Cable + ICP system acquisition : 1800g 4-20 mA wired acquisition data + 7 m of shielded cable: 800g 3 temperature wired acquisition data + 20 m of shielded cable: 2500g | |

Total weight | 1285g | 5100g |

By

eliminating cumbersome and heavy wiring, BeanAir's wireless solutions not only

streamline the testing process but also boost the vehicle's available payload,

offering greater flexibility for comprehensive testing scenarios.